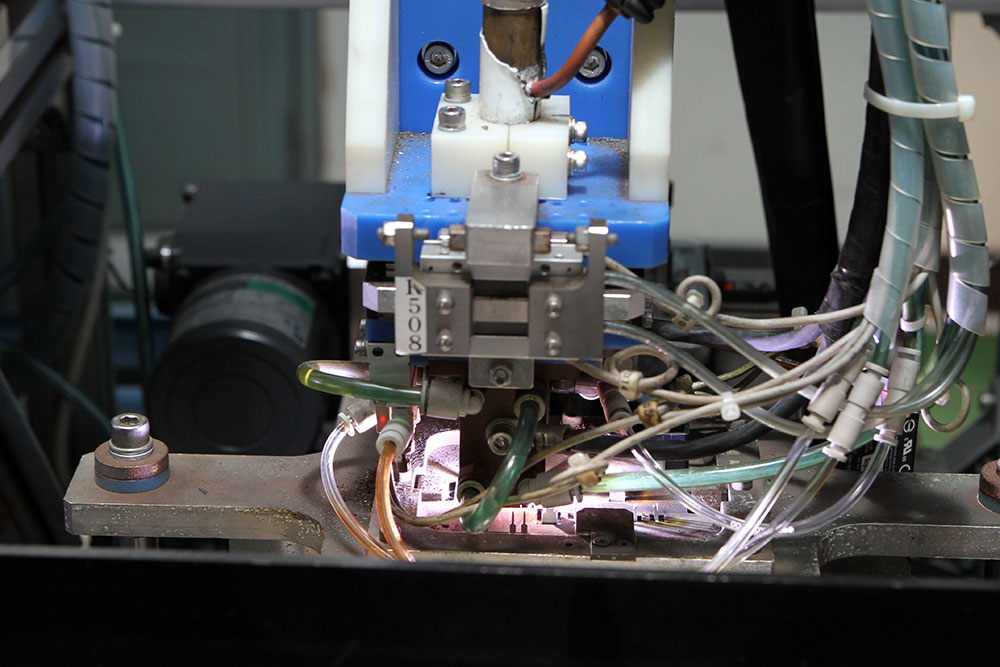

In-house Design and Manufacturing Equipment

・In-house production of machined parts is over 90%.

・Cheaply manufactured equipment

・Prompt response to equipment problems

・Self-designed and manufactured equipment with an operating rate of over 90%.

・Cheaply manufactured equipment

・Prompt response to equipment problems

・Self-designed and manufactured equipment with an operating rate of over 90%.

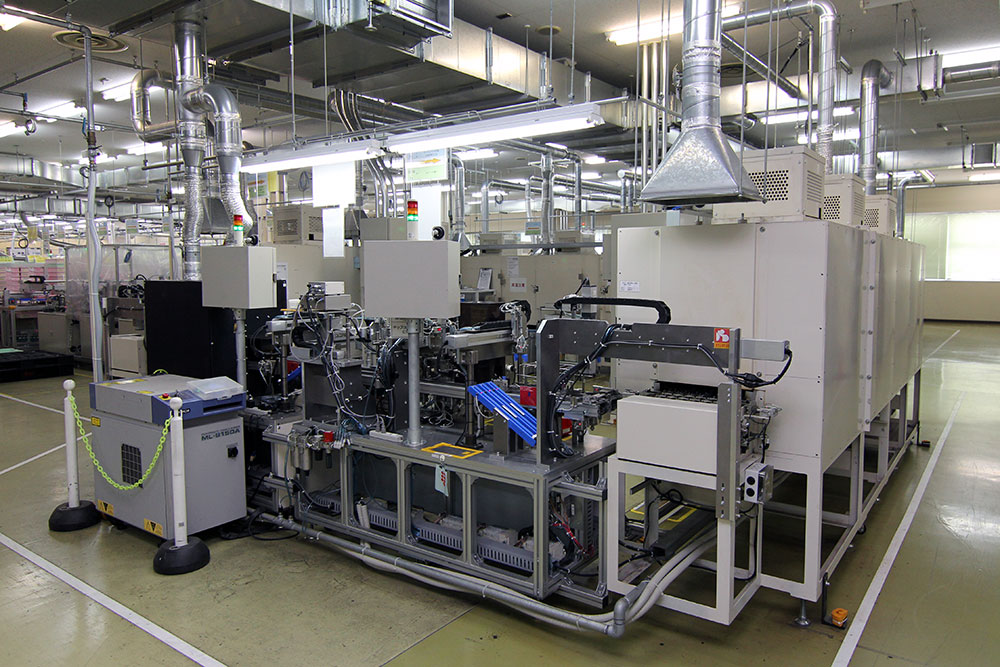

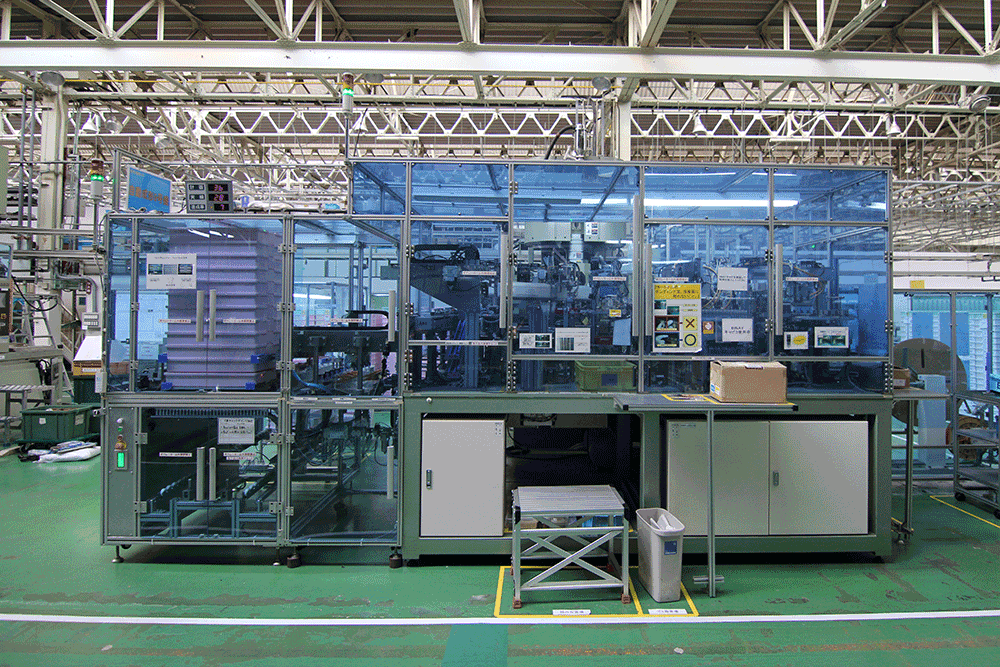

Automatic Insert Molding and Inspection Equipment

・Inspection and Boxing Line

Parts

・Aluminum Base

・Brass Terminal

・Stainless Steel Terminal

Process

1) Insert Molding

2) Gate Cutting

3) Terminal-Carrier Cut

4) Pressure Test

5) Airtight Inspection

6) Surface Scratch Inspection

7) Terminal Height・Pitch Check

8) Packing Insertion

9) Packed in a Box